- #PWM DRIVER CIRCUIT FOR STEPPER MOTOR DRIVERS#

- #PWM DRIVER CIRCUIT FOR STEPPER MOTOR DRIVER#

- #PWM DRIVER CIRCUIT FOR STEPPER MOTOR FULL#

- #PWM DRIVER CIRCUIT FOR STEPPER MOTOR SOFTWARE#

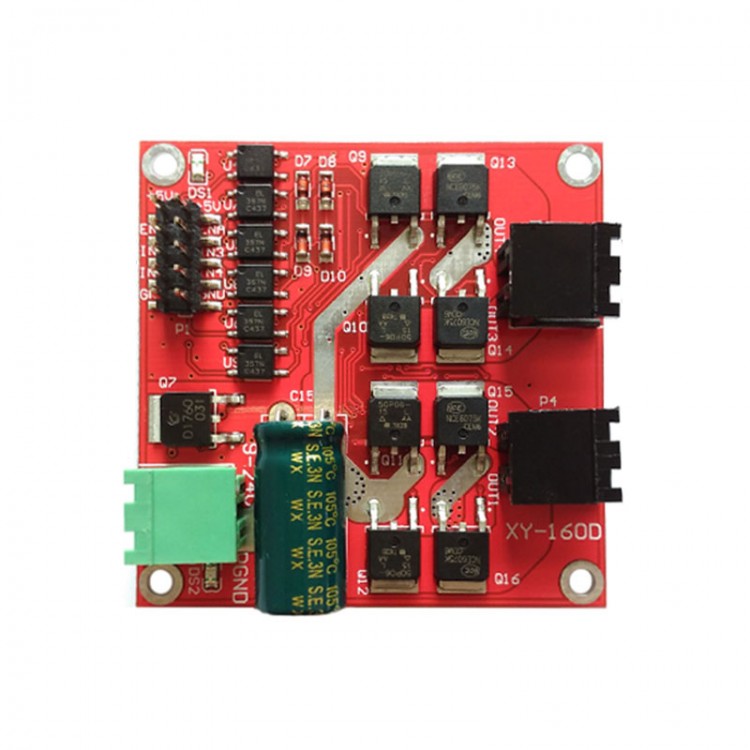

The emitters of the two low-end transistors of each bridge are connected together and led out for external detection resistance. It accepts standard TTL logic level signals and can drive stepper motors with a voltage of 46V and 2.5A per phase or below.Įach bridge has an enable input, which allows or prohibits the device to work without being affected by the input signal.

#PWM DRIVER CIRCUIT FOR STEPPER MOTOR DRIVER#

L298 is a high-voltage and high-current dual full-bridge driver with two H-bridges. The phase required by the stepping motor is generated inside the circuit, which greatly reduces the burden on the CPU.

A notable feature of l297 is that only clock, direction, and mode input signals are required. The on-chip PWM chopper circuit allows switching control of the winding current. There are three drive modes: half-step, full-step, and wave. It is suitable for the control of bipolar two-phase stepper motors or unipolar four-phase stepper motors.

#PWM DRIVER CIRCUIT FOR STEPPER MOTOR SOFTWARE#

You could use Software Timers or timed interrupts ( SparkIntervalTimer) or just use a simple non-blocking function that performs one step at each visit and keep calling it from loop() at a regular rate.īTW, I’d not keep the steppers on all the time, but rather control the /SLEEP pin with a GPIO to depower the steppers once you’re done with the movement.Standard stepper motor driver using L297 and L298 IC III L297 and L298 Hardware circuit 3.1 L297 Overview However there are non-blocking coding techniques. You could use PWM but since steppers are open loop systems, whenever your code should happen to block, your steppers will just run-away which is probably not what you want.

#PWM DRIVER CIRCUIT FOR STEPPER MOTOR FULL#

Turn PWM pin off after completing 5 full revolutions

Turn PWM pin on with 50% duty cycle and 100Hz

So if I want to turn a 200-step Stepper Motor 5 full revolutions, could I do something like the following? // record start time With my current 5ms delay between each High or Low write, that’s 10ms per cycle, or 100Hz. So I’m wondering if I can avoid all the High/Low pin writes and delays by attaching the Polulu’s Step pin to a PWM pin on the Photon and set the Frequency on that pin On and Off at predetermined times to get the number or rotations or minutes of operation that I’m looking for.įor example. It looks like AccelStepperSpark is not blocking, but is a quite long and involved library, as it should be to cover all options/configurations. I read through several Stepper threads here, but saw a comment that the Stepper library can be blocking as well. This of course causes the program to be blocking while any stepper is turning which I’d rather not do as several gardening functions run for several RPMs or minutes at a time. Somehow I overlooked the Stepper libraries in the Photon Web IDE and programmed them myself using for() loops and setting the step pin High then Low with a 5ms delay in between. I currently have 2 motors wired up and working with the supplied wiring diagram from Polulu.

#PWM DRIVER CIRCUIT FOR STEPPER MOTOR DRIVERS#

I’m currently driving the steppers through Polulu - DRV8825 Stepper Motor Drivers which is working well, and I appreciate not having to burn 4 pins per motor. As it’s a garden and not a 3D Printer, it doesn’t need super accurate stepper motor control down to the microsecond or individual step resolution. I’m working on a project for a garden control device which includes a couple stepper motors.

0 kommentar(er)

0 kommentar(er)